Stick, MIG, and TIG Welding Steel!

As you start welding steel you'll find that you will be welding mild steel and stainless steel more than any other metal. Unless, of course you have a particular project you want to create that requires aluminum welding, brass or bronze welding, or cast iron (among other metals).

I guarantee you will enjoy welding mild steel because there are no challenges you will encounter, relatively speaking, except for learning how to weld in general.

You can easily weld mild steel (or low carbon steel) using the different processes like Stick, MIG, Tig, or Gas Welding.

If you are new to welding you should either MIG weld or Stick weld it. TIG and Gas welding are a bit more advanced (but don't let that stop you. I know many welders who learned to Oxy Acetylene weld first which was a great base welding process to learn). I digress...

What Is Mild Steel And Why Is It Easy To Weld?

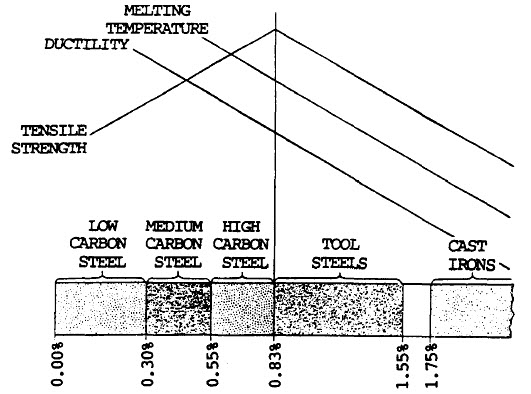

Mild steel is the easiest metal you will weld due to the carbon content. Carbon makes steel harder, and mild steel is a low carbon steel.

The amount of carbon in low carbon steel is .3 percent or less. The majority of mild steel has about .10 percent to .25 percent carbon. In addition to carbon there is Manganese which amount to .25 percent to .50 percent. The other elements included in low carbon or mild steel are Phosphorous .40 percent (at most), and Sulfur .50 percent (at most).

Conversely, cart iron has a carbon content of 2.1 percent and up to 3 percent (and sometimes a bit more), which makes it more challenging to weld.

How Steel Qualities Change As Carbon Is Added:

Mild steel does not get as hard as other metals do when you weld it, and

it does not require you to pre-heat the metal. In addition you rarely

will almost never have to do any post-heating either (this is only done

if you are going to weld large pieces of metal together which you

probably will not be doing any time soon).

Mild steel is a

versatile metal. It can be worked in many different ways because it is

both soft and ductile (it can be hammered thin, it can be drawn out into

wire). It can be worked on whether it's cold or hot, and it can be

machined, sheared, rolled, and punched.

Stick Welding Steel:

Consult the manual that came with your welding machine, but generally speaking you can use thin or heavy coated welding rods on mild steel. These types of electrodes have a carbon type of .10 - .14 percent. I use 6011 or 7018 rods. Some like the AC7018 because it supposedly re-strikes really well, but the 7018 is fine. The other electrodes to try are the 6013 and the 7014.

I mention these other rods because everyone has their own taste so it's a good idea to experiment.

Low carbon, copper coated stick welding rods should be the rods of choice when welding mild steel.

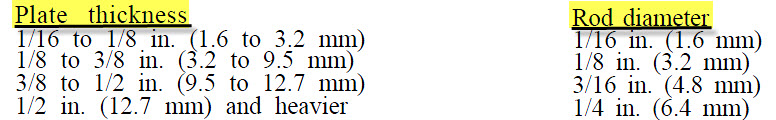

Here Is A Chart For The Arc Welding Rod Sizes Based Upon The Mild Steel Plate Thickness:

Attention: Stick welding electrodes from 5/16 inches to 3/8 inches (or 7.9 millimeter to 9.5 millimeter) can be used for heavy welding procedures. But keep in mind that you can make heavy welds with 3/16 inches or 1/4 inch rods (or 4.8 millimeter or 6.4 millimeter) as well.

When using these thinner stick welding electrodes you will need to be able to control the electrode melting rate as well as control the puddle properly.

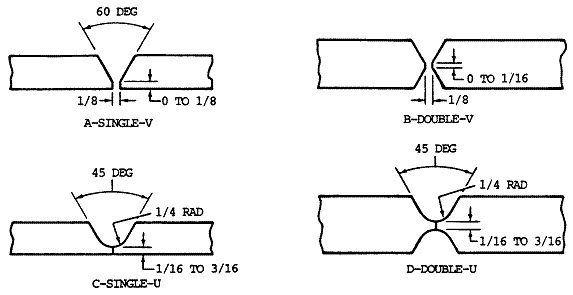

Weld joint preparation can be accomplished by either machining it or using flame cutting procedure. The kind of weld preparation you will use is depended upon the thickness of the metal plate and the welding position.

MIG Welding Steel:

Welding steel is a breeze with MIG. All you need is your MIG welder with the right wire (and gas set up), and you are ready to go.

There are basically two different and common types of wire to use for MIG welding steel. They are:

ER70S-3: This is your standard wire. It's a general 'all purpose' wire for welding mild steel. You will use this more than any other wire, assuming you are welding mild steel.

ER70S-6: If you are going to weld steel that is rusty or dirty this is the wire to use because it has more 'deoxidizer' in it.

The wire diameter is another issue: But for welding mild steel you will be using .030 inch wire. If you will be welding thinner metal then you may want to use the .023 inch wire because it will reduce the amount of heat input. Conversely, if you will be welding thick metal you will go up to the .035 inch wire (and there is also .045 inch wire but your welder may not have the output for this thicker wire).

Consult your MIG Welder handbook for wire type and settings based upon the metal type and thickness you will be welding.

Tig Welding Steel:

Once you learn how to TIG weld you are probably not going to want to MIG or Arc weld as much because it's more versatile and produces nice strong welds. It's versatile because you can weld just about any kind of metal with it, and you can weld very thin material. And I am talking as thin as a Coke can or a razor blade.

Welding steel that is thin is hard to do with MIG and Stick welding, and you are limited to the types of metal you can weld. That's not to say MIG and ARC welding are inferior though. I am not going to get into that right now.

To TIG weld mild steel you will select the right tungsten and filler rod, get your settings right, and then off you go. The cool thing about TIG welding is that you don't have to switch very much if you need to weld different metals.

For example, if you were going to switch from welding steel to welding aluminum all you have to do is choose a different filler rod and change a few settings on your machine. You'll probably need to switch your TIG welding machine from DC to AC of course. And that's all there is to i. Check your machine handbook for the exact settings for the metal you are welding.

And the welds are clean and gorgeous, and there is very little to no cleanup (there is plenty of clean up with Stick welding, and varying amounts with MIG welding).

Now if you have a MIG welder and you swtich from welding steel to aluminum, not only is it harder to do but you have to make some adjustments. You'll need to swap out your torch for a spool gun or maybe a push pull gun (both can be expensive). Some guys just swap the cable out for a shorter cable and run the wire through that way (if you run aluminum welding wire through your wire feed machine and you have a standard cable it will get jammed up). But a spool gun runs thin wire on a spool so that it does not jam up in your Thin aluminum welding wire is required for welding aluminum with MIG.

In addition you have to change settings and gas on your MIG welder.

I don't want to get into the pro's and con's of MIG and ARC welding because I enjoy those processes and they do just fine, and they are much easier than learning to TIG weld.

Related Article:

Galvanized Steel?Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: