How To Weld Cast Iron!

Welding cast iron can be pretty frustrating. I've done everything right (pre heat, post heat, slow cooling) and had it crack while it's cooling. I've also welded some up and thrown it in the back of a snow filled pick up truck still hot without it cracking. It probably has to do with the quality of the cast, and there's no way to tell that.

In general, it's the cooling that causes problems, so preheating a large area around the weld will help (the whole piece if you can). After the weld, a post heat will help even out the cooling.

The type of weld is pretty important. If the pieces being joined are

free to move, like a bracket, welding cast shouldn't be a problem.

For pieces that are trapped or large, like fixing a crack in a bell

housing, post heating a larger are and forcing it to cool slowly are

important. In some cases, brazing welding is better. While it isn't

as strong, it isn't as hot and doesn't cause as many problems.

I don't know exactly what they are trying to weld, but make sure

it's cast iron and not cast steel. Cast steel welds easily with

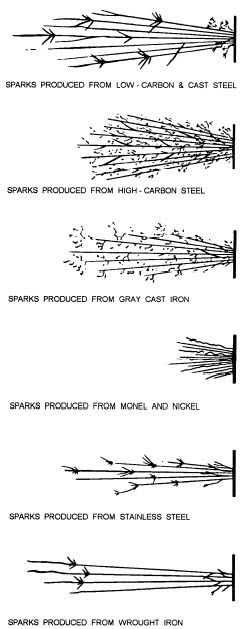

7018. There's a "spark test" using a grinder and watching the

sparks.

Cast iron is good for conducting heat, but it's fairly brittle. Especially what cast iron (there are two cast iron types: white and gray).

Cast iron is resistant to wear but it's also not very malleable. It is also good for conducting heat and that is why you see cookware made from this material. However, it's brittle and that is why you don't see any structures built using cast iron.

How To Tell If You Have Cast Iron!

The reason you want to know what type of material you have is because you will use a different welding process for different types of material. Also, some material requires pre-heating, and others do not. So if you try to weld something without pre-heating, and it is required, you are in for a big problem.

The oldest and most common way to tell if you have cast iron is to use what is called spark test. You accomplish this by holding the metal to a grinder and analyze the sparks it creates.

The sparks that shoot away from your material and grinder follow what is called a 'carrier line'. It's easier to follow the carrier line if you have a dark background to the sparks.

How long, short, or non-existant a spark is will tell you what kind of material you have.

Oxygas Welding Cast Iron?

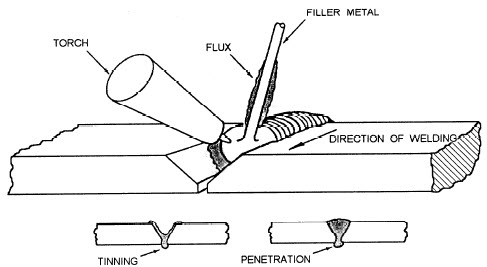

Another way to weld cast iron is to use the oxygas welding procedure. It's actually used very often and many welders favor oxygas for this material. However, you will need to follow a few guidelines to accomplish a decent weld.

- A V groove is needed on material that is 3/16" - 3/8" should have a V butt joint at sixty degrees.

- If your cast iron is 3/16" or less you don't need a V groove.

- If your material is 3/8" or more you'll need a double V butt joint at 60 degrees.

- Preheat your cast iron welding area. 750 - 900 degrees (Fahrenheit).

- Use a neutral flame when welding. Use the backhand technique.

- Your filler metal must be cast iron along with the right amount of flux.

- You'll want to guide the inner flame cone up against the filler rod rather than actually dipping the rod in the molten weld puddle.

- Do not use more than 1/8" thick deposits of filler material from your rod.

- Many welders agree that you need to heat the weldment after you complete the welding anywhere from 1100 - 1150 degrees Fahrenheit to relieve stress in the weldment, and then allow it to slowly cool.

Backhand braze welding cast iron.

Backhand braze welding cast iron.The reason Oxygas is used often to weld cast iron is because it provides a more aesthetic weld in terms of color and texture. But if the color is not important a less expensive and potentially easier alternative is to braze weld cast iron.

We have a section on braze welding coming soon so please be sure you are on our list to be notified when this page is live. Thank you.

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: