Build A Bench Top Bender!

In this detailed tutorial you are going to build a bench top bender that bends rod and bar stock for your decorative welding and metalwork projects.

This bender can bend up to 1/2" diameter rod or 1/2" thick flat bar.

It's a good quality tool that won't cost very much to make. All you pay for is the materials which should not be much more than $90, depending on the cost of steel at the time or your purchase.

You can buy a new or used Chinese made bench top bard and rod bender for just under $90. But then you have a Chinese made bender that will work, for the time being.

How The Bench Top Bender Works:

This bench top bender can be bolted to any surface with four 3/4-10 bolts. It can also be welded or clamped down.

Directions:

- The pin which connects the fixed and rotating arms is the point where the material will bend.

- Sandwich the material between the pivot pin and the pin on the fixed arm.

- Rotate the movable arm until it's pin also sandwiches the material between the pivot pin.

- Now bend to the desired radius.

- For different sizes and lengths the pins are adjusted in the arms.

For simple visual operating instructions of a similar bench top bar and rod bender search for the 'harbor freight bender' on YouTube or watch this video (it's a little shaky):

|

|

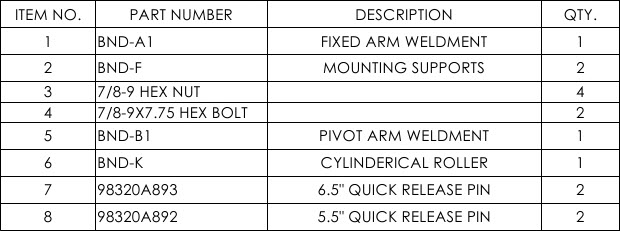

Bill Of Materials:

- (10 FT) Hot Rolled Steel Flat Bar, 3” X 0.500”

- (40 IN) Steel U-Channel, 3” X 1.5” X 0.250”

- (20 IN) Angle Steel, 3” X 3” X 0.500”

- (20 IN) Steel Rod, 1-3/8” Diameter (BND-E)

- (4 IN) DOM Round Steel Tube, 1.25” OD x .095” wall x 1.060” ID (BND-K)

- (2) 7/8-9X7-3/4” Long Hex Head Bolt

- (4) 7/8-9 Hex Nut

- (2) 5.5” Zinc Plated Steel Quick Release Pin (Mcmaster-Carr #98320A892)

- (2) 6.5” Zinc Plated Steel Quick Release Pin (Mcmaster-Carr #98320A893

8 Steps To Building A Bench Top Bender!

We have a 12 page set of blueprints for these bender plans if you need more detail. However you may find that the following illustrations and directions are enough. Just let us know if you need them.

Step 1: Cut stock to length.

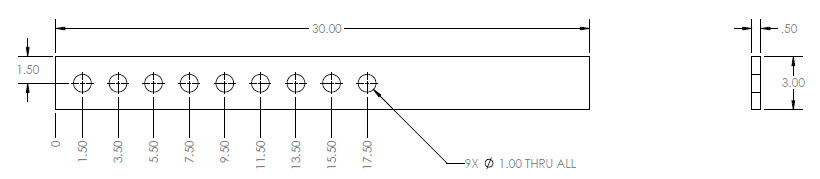

- Cut 3” X 0.500” Flat Bar into 4 pieces of 30”.

- Cut 3” X 3” X 0.500”Angle Steel into lengths of 5-5/16” (qty 2) and 4-1/8” (qty 2).

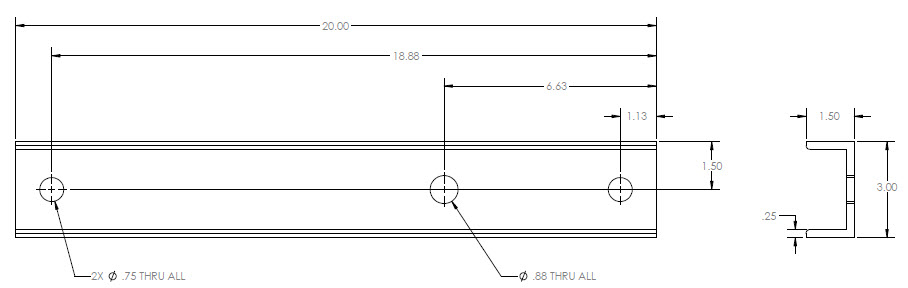

- Cut 3” X 1.5” X 0.250” Steel U-Channel into 2 pieces of 20”.

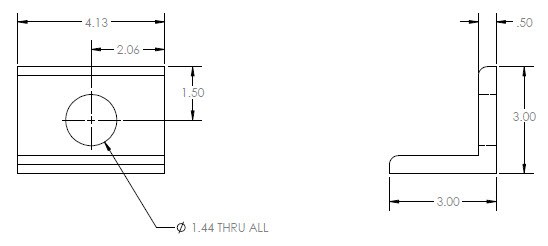

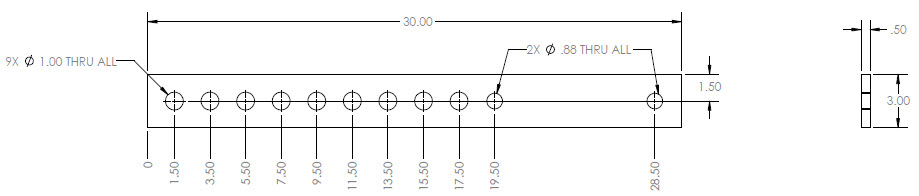

Step 2: Clamp two 30” pieces of the cut flat bar together and machine according to the bench top bender drawing BND-A below. This will make 2 identical pieces.

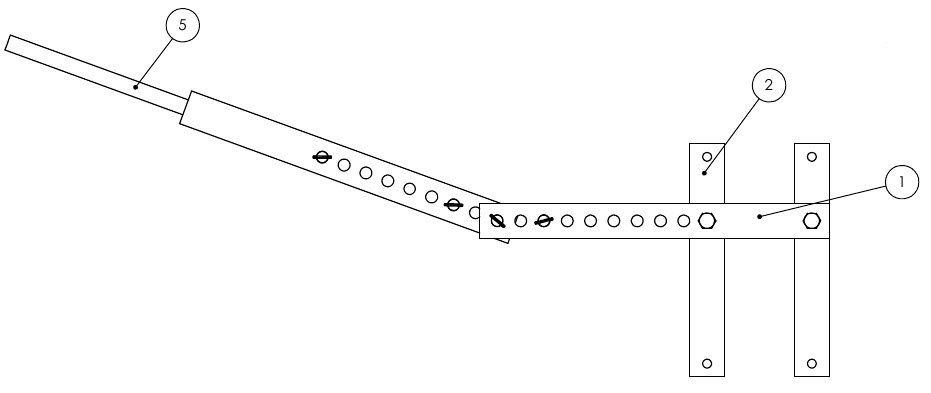

BND-A: Fixed Arm

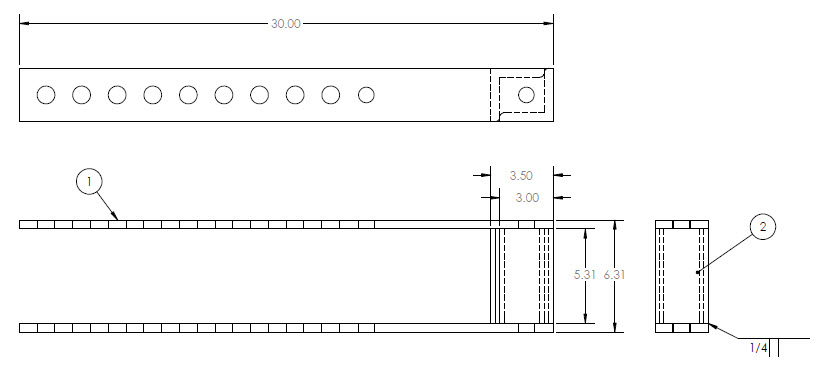

Step 3: Clamp two remaining 30” pieces of the cut flat bar together and machine according to drawing BND-B. This will make 2 identical pieces.

BND-B: Pivoting Arm

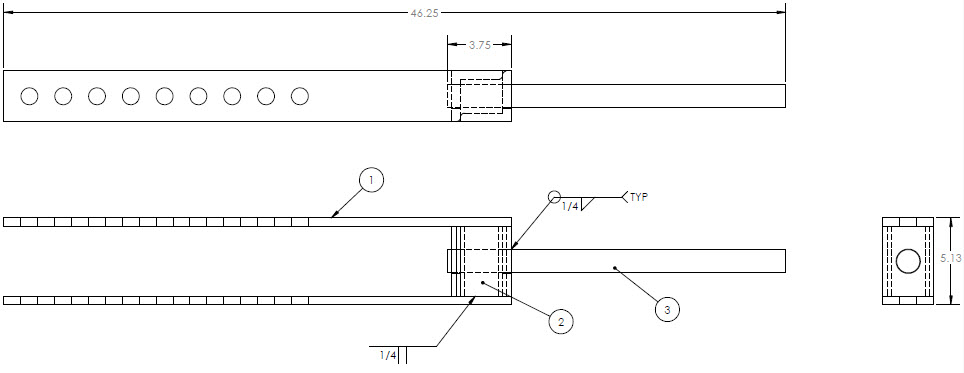

Step 4: Clamp the two 20” pieces of the U-Channel together and machine according to drawing BND-F. This will make 2 identical pieces.

BND-F: Mounting Supports

Step 5: Clamp the two pieces of the 4-1/8” long angle steel together and machine according to drawing BND-D. This will make 2 identical pieces.

BND-D: Pivoting Arm Box

Step 6: Gather parts BND-A (qty 2) and both the 5-5/16” angle steel pieces (BND-C) and lay them out on the welding surface. Position them according to the bench top bender drawing BND-A1 and tack weld the parts in place. Double check alignment and complete the welds.

BND-A1: Fixed Arm Weldment

Step 7: Gather parts BND-B (qty 2), BND-D (qty 2), and BND-E and lay them out on the welding surface. Position them according to drawing BND-B1 and tack weld the parts in place. Double check alignment and complete the welds.

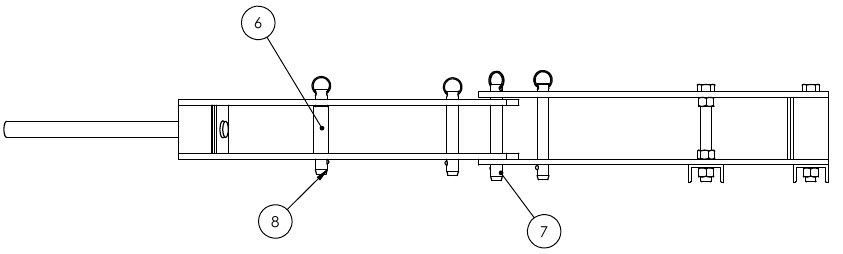

BND-B1: Pivoting Arm Weldment

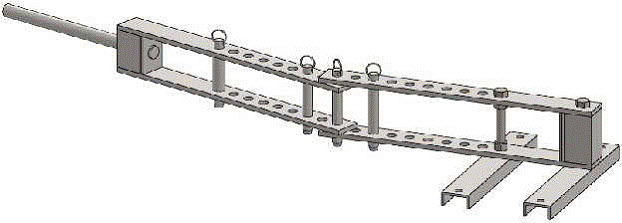

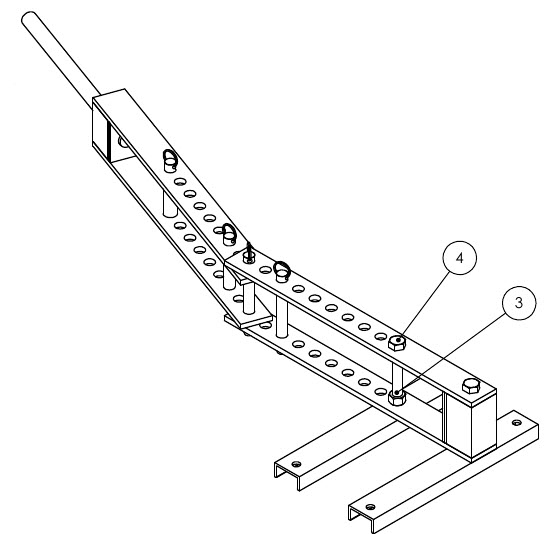

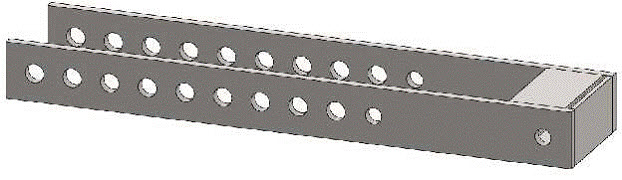

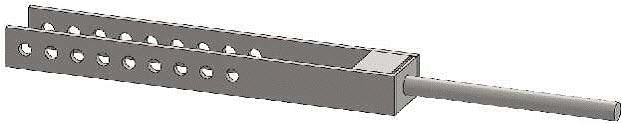

Step 8: Gather all components and place on work bench. Assemble pieces according to attached print BND-AA and below drawings

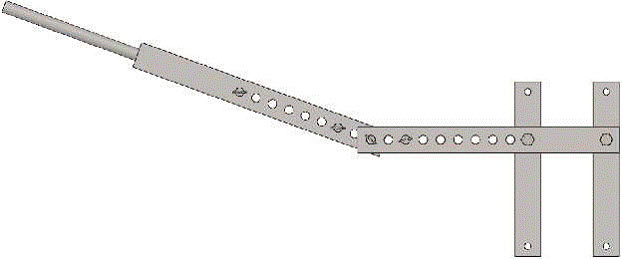

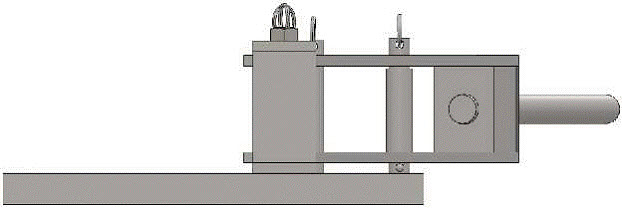

Completed Bench Top Bender:

Refer to the parts list at the beginning for the following weldments.

BND-AA: Bending Machine Assembly 1

BND-AA: Bending Machine Assembly 2

BND-AA: Bending Machine Assembly 3

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: