Arc Welding 101!

Arc Welding is also referred to as stick welding because you will be using an electrode to lay your weld bead and it looks like a stick.

The technical term used to describe this welding process is Shielded Metal Arc Welding or SMAW.

This guide is at least going to be basically enough to get you started because there is a lot of stuff to learn when you are welding for all positions and different kinds of metals.

Lets start with the bare bone basics:

First, use a full-face shield so the electromagnetic radiation coming off the light from welding does not burn the hell out of your face and ruin your eyes and use a dark light filter like a #10 darkened screen glass.

The most common every day type of arc welding machine (stick welder) used in a garage or just for general fabrication, or if you are a

backyard mechanic, is an AC 220 volt 250 amp output electric

welder:

This Canox AC welder has no selection for using with DC which are special rods for more exotic kinds of welding. They are kind of cheap too. They range anywhere from 250.00 to about 400.00 brand new and they are really simple to wire up.

You can just wire them up to a circuit that you use for something like a stove or something like that, and use as 40 amps on 115 volts for each wire.

You can adjust how many amps output they have either by cranking a lever or moving up and down a lever.

Either way it works just as well and the rule of thumb is for every thousandths of an inch thick your rod is, like for example an 1/8 thick rod is 125 thousandths it would likely work best welding around 125 amps.

If you want to weld with a ¼ inch welding rod well then you will need close to 250 amps but maybe only 225 amps if that is all your welder has.

These welders are good for arc welding steel which is usually more than 3/16 of an inch thick because they are very powerful and they don’t seem to arc very well with amperage less than 100.

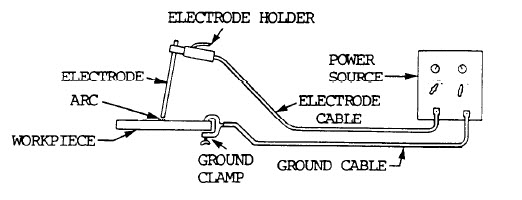

Schematic Shows A Typical SMAW Setup:

The Shielded Metal Arc Welding process is often used to weld low and high alloy steels and structural steel. Pipe welders use this process frequently. Also, it can be used on nickel, copper, and aluminum alloys.

Since arc welding requires basic equipment and it can be utilized in flat, vertical, horizontal, and overhead welding positions, it is very good for mobile welding work, and outside fieldwork.

Welding Rods:

Below are 1/8th inch rods and 1/16th inch rods (or maybe a 3/32nd). It could be a little bit more.

If you have one of those 115 volt welders that put out only about 75 amps or so, these small rods are really hard to work with. It is really hard to get arcs going on these skinny rods, but it's very easy on the larger rods which are 1/8th of an inch diameter or more.

To use these tiny arc welding rods you almost have to already be an expert in using the other type of larger machines just because they are so hard just to weld with. They just don’t want to carry the spark.

The AC 220 volt 250 amp welders produce a lot of heat with welding and they

have very good penetration for doing structural welding or fabrication. Almost too much penetration if you are using

them on thin metals and they are absolutely useless trying to weld cars unless

you are doing a frame.

How To Arc Weld Thicker Metal:

If you wanted to make a strong weld with a thicker piece of metal with one of these you would grind a 45-degree chamfer all the way along the edge of both pieces that you are going to weld together so that you are dropping your weld blob into a “V” so you would have like a “V” all the way along the surfaces, that would give you good penetration to the other side and a larger surface area for the weld to attach to on both chunks.

If you want to do a weld to a part that is going to held 90 degrees to the other one you would be a couple of a little tack welds on each side because when you weld and the weld starts to cool it is going to suck the part right over to a position you don’t want it to be and the tack welds prevent that from happening, or at least prevent most of it from happening.

When you are doing a 90-degree weld you don’t need to do any grinding or chamfering just run your bead along and also tack the other side so it doesn’t bend over when it cools.

Luckily the AC 220 volt 250 amp Arc welding machines are less

sensitive to slag or the coating that is on hot rolled metal or to rust

compared to mig welders.

Stick Welding and Slag:

- Mig welders just hate welding to any foreign material because it releases a bit of oxygen.

- The disadvantage of arc welding is this process produces a flux coating on top of your weld called slag and if you are not doing a good job of welding you get slag inclusions in your weld which are little pockets of flux that will weaken your weld.

When you are done welding with an arc welder and you’ve got a bead of weld it is going to be coated in the slag so use your chipping hammer to chip it off if you want to restart the weld and continue it along or you will end up getting a slag inclusion where the two welds meet.

E6013 Rods:

The welding rod above is called an E6013. This means it has pretty good penetration but still a decent and smooth looking weld that is esthetically nice looking when you are done. It is 1/8th inch so it welds best around 125 amps and they are fairly cheap.

- If you want a rod that has less penetration you know like doing thinner metal or metal that isn’t as important to get penetration with and you want a beautiful weld get yourself 7014 or 7018 rods.

- If you want a high penetration rod for doing strong structural work or frames that are thick enough get yourself a 6011.

Now those are not the only types of rods you can use, you can ask your welding supplier or look it up on a chart or book what kind of rod may be more suitable for your application.

Rod Storage and Spatter:

It is very important not to let your rods get wet or damp or this will start to happen. The coating will start to flake off and it will especially start to flake off as soon as you start to weld then your arc will all spatter and be horrible and your rods will become useless.

A very good place to store your rods is in a broken down fridge or freezer because they have a rubber seal on the door and it keeps them very dry pretty much forever.

Striking The Arc:

One of the hardest techniques to get used to when you are arc welding is striking the arc so when you’ve got your ground connection connected to your piece of metal you have to sort of hold your rod whatever position you find comfortable.

I find near vertical or up to a 45 degree angle just fine, but you have to give it little strikes where you actually touch the two pieces together and the end is already cleaned a little bit to make that easy.

As soon as it

starts to arc you have to hold it about a 1/8th of an inch away and

maintain that gap to keep the arc working properly and to have your weld turn

out nice. Then when you are welding you

are zigzagging it our doing little curves as you weld.

Now I am going to show you how to strike an arc and how to

just run a bead...

Remember always wear something to cover all the skin on your body and wear a full-face mask. Once the tip turns red hot it starts to arc easily. Simple as that...

It is a good idea to wait until the weld cools before you start chipping off the slag because the slag is super-hot and it will stick to your eyes, melt your glasses, burn through your clothes, and when it gets cool it just starts to flake off by itself.

It makes like crinkling sounds. So this weld looks pretty decent and the slag came off no problem.

MIG Versus Arc Welding:

Most people think that stick welding or arc welding is more difficult than MIG welding or wire feed welding. I guess I have to agree.

Mig welding, or wire welding, is more like using a hot glue gun because the temperatures are a little bit lower and the blob or molten blob of steel is a little bit less runny and easier to control and there is no slag.

But the 220 volt 250 amp AC Arc welding machines work excellent outdoors in any amount of wind. They are so much cheaper to purchase.

Sure you have to hook up 220 volts in most applications to make them work, but they are just so simple.

They just need a bit more finesse in controlling the penetration so you don’t burn through or have your molten blob just drip and fall off or something like that and they work very well on materials that have a little bit of coating or slag on them even a bit of paint or a bit of rust. They seem to just go through that no problem.

Need a project? Try this simple project to get you motivated.

Related Articles:

What Did You Think?

So there you have it. A basic guide to arc welding. I hope your found it helpful. If you did can you please like the page or share it? Use these little buttons below to do that for me, ok?

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: