Weld Types Explained!

There are quite a few weld types that you should understand. And we are going to discus the big 8.

You should have a firm grasp of what each of the eight types of welds if you are going to be welding more than the average home DIY hobby welder.

It's also important to understand the differences of joints and the actual welds if you are going to fully understand the weld joint.

The best way to describe a weld is to take a look at the actual shape of the cross section of the weld. Fortunately all the welds and joints and even most of the welding processes take on common names so it's easy to understand and learn.

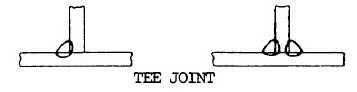

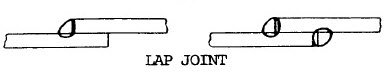

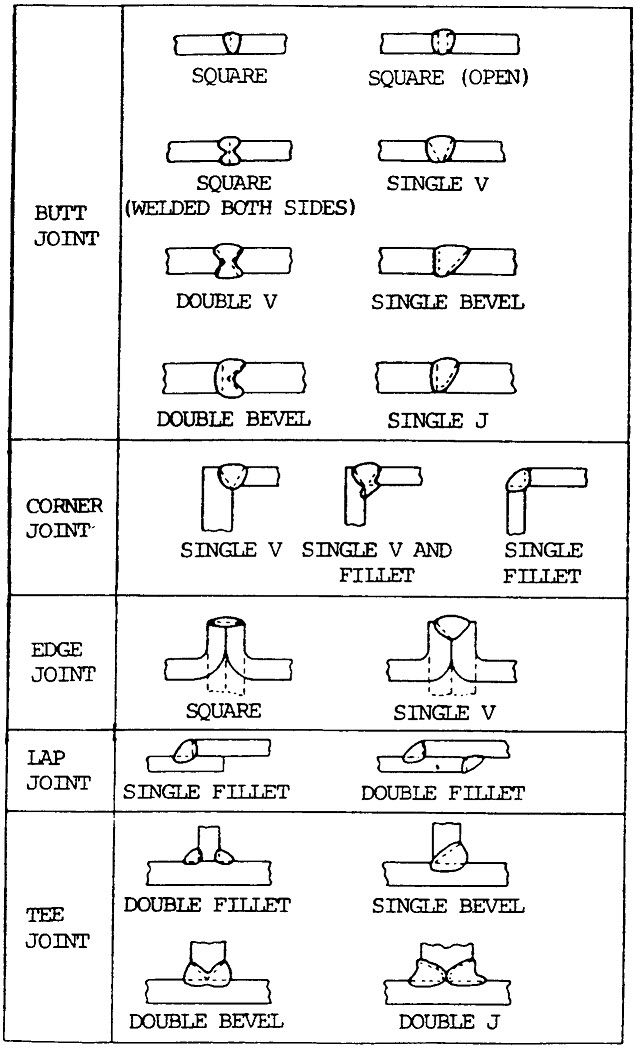

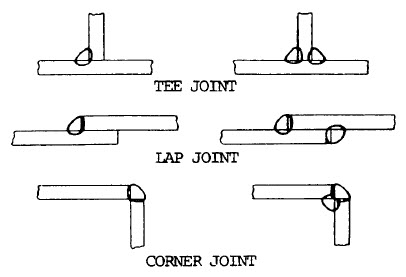

First here are common joints where the weld will be performed:

Fillet Weld:

The fillet weld is the most common weld type. The types of fillet welds are shown here:

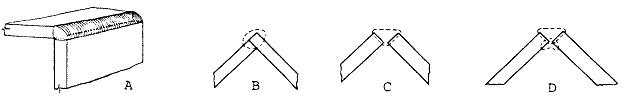

Groove Weld:

Groove welds are also a very common type of weld and there are seven of them:

To make a weld joint you must combine both the weld and the joint, which is common sense, right?

Typical Weld Joints:

How the surface, seam, or joint is prepared is directly related to what weld type you will use.

Welds Types Explained:

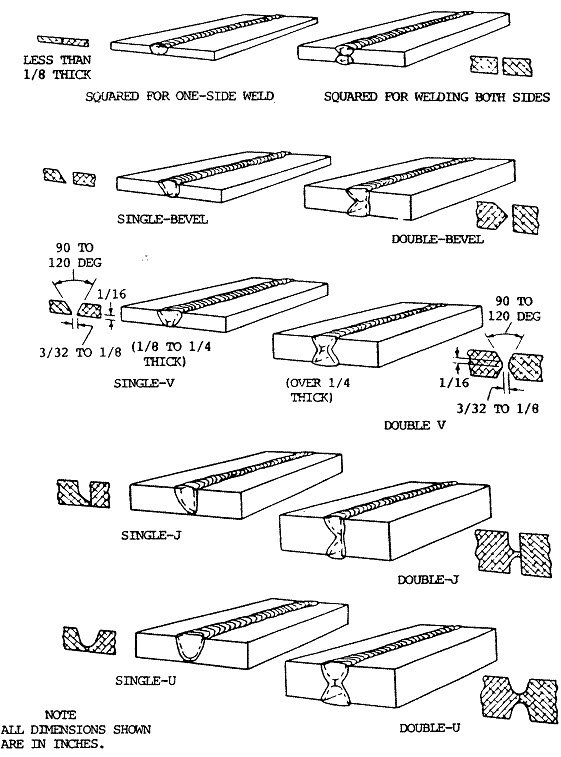

Groove Welds are basically weld beads that are put into a 'groove' which is between 2 pieces of metal that need to be jointed.

Groove Weld Chart:

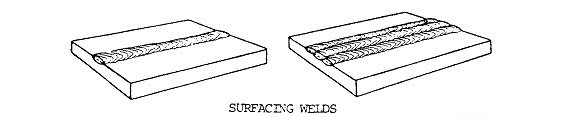

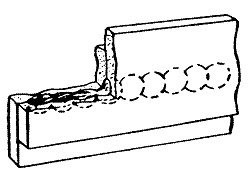

Surfacing welds are comprised of more than one bead (string or woven) that you put into a metal that is not broken. There's no gaps or grooves. You use surfacing welds to give new life to metal that is worn. You can use surfacing welds on butt joints as well.

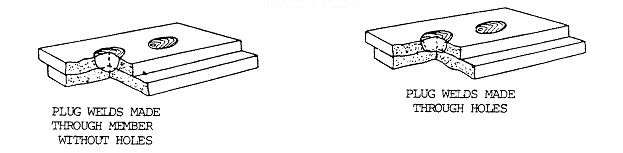

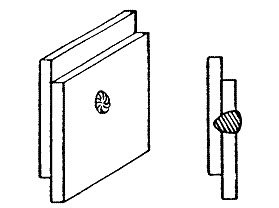

Plug Welds are welds that are in a circular shape...a hole. Put simply you will fill a hole with your weld metal and therefore join the overlapping pieces of metal together. The top piece of metal will have the hold which penetrates through to the surface of the bottom metal. The holes are not always aligned but you would use your weld metal to fill the hole, often replacing a rivet, and therefore join the top and bottom pieces of overlapping metal together.

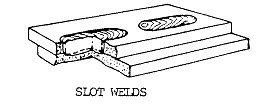

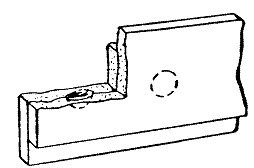

A Slot Weld is just like a plug weld. It is made in a hole that is in a lap joint or a tee joint which joins the metal to the top of the other piece of metal underneath it. A hole on the top piece in this case is a 'slot' or elongated hole which exposes the bottom piece of metal. You then fill the slot with your weld metal to join the two overlapping pieces of metal.

A Fillet Weld is basically a weld that is in the shape of a triangle (or that is the closest shape one can attribute to it) if you were looking at the weld bead cross section. This fillet weld is created to join two pieces of metal together in right angles:

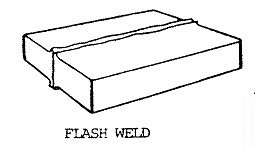

A Flash Weld is simply a weld created by using the flash welding process. It's used mainly industrial situations and creates welds fast.

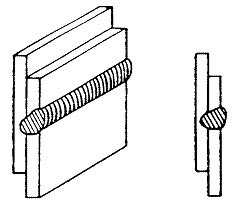

A Seam Weld is created using the welding processes called arc resistance seam welding or arc seam welding.

A Spot Weld is created using the process called arc spot welding or resistance spot welding.

An Upset Weld is simply a weld created using the upset welding process.

Recommended Articles:

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: