Underwater Welding Guide!

Most underwater welding was wet welding up until about 1965.

The other techniques used are to build cofferdams and caissons (see below) for major structural engineering.

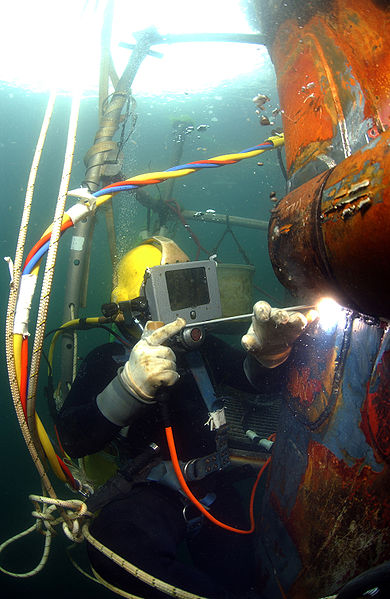

Wet welding is where the welder diver and the actual weld are underwater, and the process used is mostly stick welding (shielded metal arc welding).

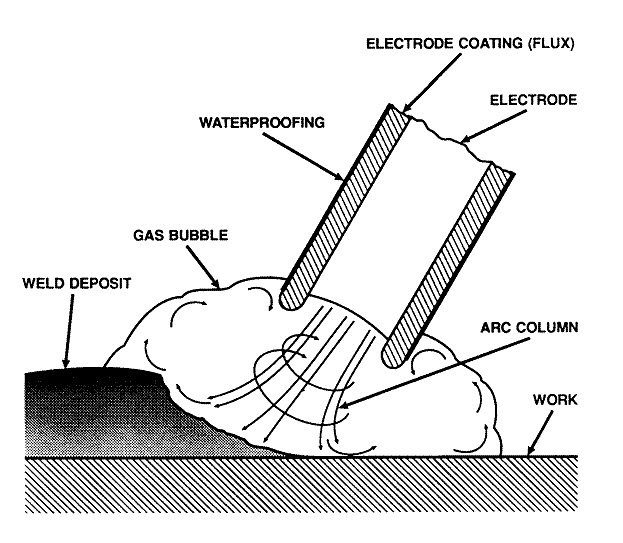

Wet welding using the shielded gas metal arc process (stick welding) is different than dry welding in that the gas used creates a bubble when you are underwater, which is a major factor in creating a weld:

The bubble is an important factor in the underwater welding process because pressure is built up in the gas bubble and it allows the molten pool to form and therefore form a bead like a regular welding procedure.

The weld travel speed and the length of the arc have to be just right because otherwise the bubble formation becomes unstable or it completely breaks down. Without the gas bubble you cannot weld underwater.

In addition to wet welding there are three more underwater welding techniques that can be used that take the welder out of the water so that they can perform a dry weld, which is better way to weld overall.

The use of a Cofferdam takes the water out of the equation, and they are built at the edge of a body of water (or a spray zone) as seen below. A cofferdam is used for many reasons but for welding some of common uses are for repairing ship and boat related projects; hulls, docking facilities etc.

Cofferdam Example:

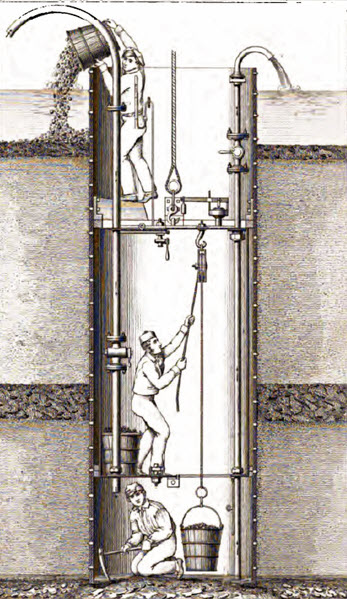

Caisson Example (From The 1800's):

Caissons are also used in similar ways to cofferdams...

A 'mini habitat is another way to weld underwater. Here's how this works: The welder diver is submersed and places an enclosure around the area that needs to be welded. Then, gas is used to pump the water out of the enclosure. The welder diver performs the welding procedure by putting only his hands and welding torch in the enclosure.

In some cases the welder diver enters the enclosure. This method is only used in special cases. Water visibility must be good, and the enclosure is sometimes see-through.

Underwater Shielded Metal Arc Welding Basics:

Stick welding or shielded metal arc welding is the process most commonly used in underwater welding. The way it works is that an arc is formed between the water proof electrode and the metal surface being welded. The heat from the arc reaches anywhere from seven thousand degrees to eleven thousand degrees Fahrenheit.

This intense heat forces the melting of the base metal and the electrode filler metal (and bits of the covering on the welding electrode). Little globs of molten metal are sent through the arc with such force that they form a weld bead on the base metal (the work). They do not drip. They are forced onto the metal. Otherwise if you were dripping globs of molten metal on your work it would not work if you were in the overhead welding position.

The electrode is special in that it has a covering called 'flux' which helps protect or shield the weld from contaminants during the weld.

Advantages To Wet Welding!

Caissons, Cofferdams, and mini habitats are all ways of creating a dry weld. If dry welds can be performed then it's a better way to go than wet welding. However, wet welding is faster, and much less expensive than the dry welding techniques.

See, a welder diver has more freedom beneath the water so he can get to areas of a structure or a ship that cannot be gotten to by other methods.

Also, Small patching projects on hulls of ships is a common wet welding job because it's simple and does not require an expensive dry welding cofferdam or mini habitat.

Also, you can get together a welder diver and get him to a hard to get to site quickly, and you can submerse him to weld very quickly as well.

About Underwater Welding Of Ships Hulls:

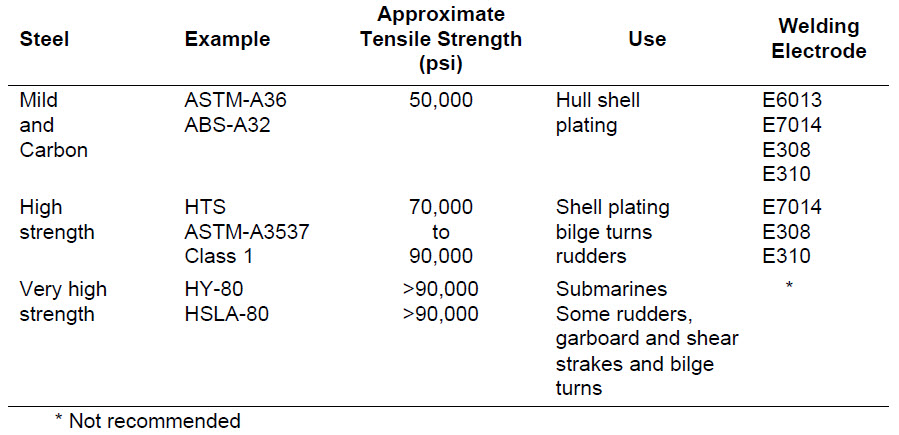

Ships hulls are built with different steel types. For example, the keel of a ship may be made of a higher strength steel than the rest of the ship. This makes sense because there's more stress on the hull in these areas.

Since the steel is different you have to select a different welding electrode to weld it. Steel electrodes are usually better for high strength steel.

Wet Welding Electrodes and Steel:

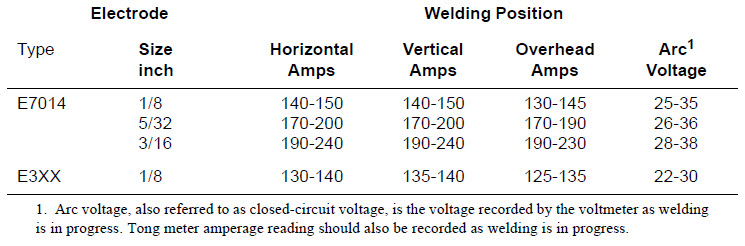

Wet Welding Currents and Volts At 50 Feet Of See Water (FSW):

Polarity and Welding Underwater!

Using Alternating Current (AC) is never used for underwater welding or cutting. It's too damn dangerous! If you get shocked in AC you will not be able to control your hands, and therefore you won't be able to let go.

Straight polarity is most often used in wet welding. Using Direct Current Electrode Negative (DCEN) will provide the diver with a longer lasting stick holder (it holds the electrode).

DCEN is not always used though. Sometimes welder divers use Direct Current Electrode Positive (DCEP), which is reverse polarity. This chart gives you some examples of when this might be appropriate:

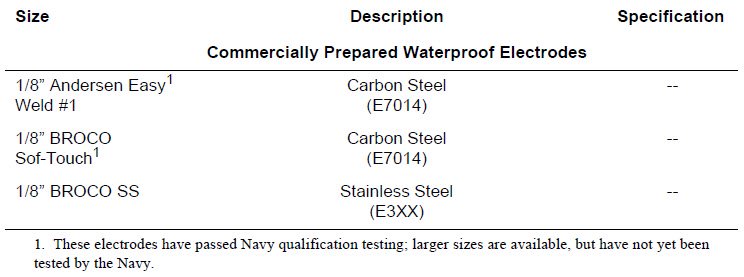

Commercial Waterproof Electrode Chart:

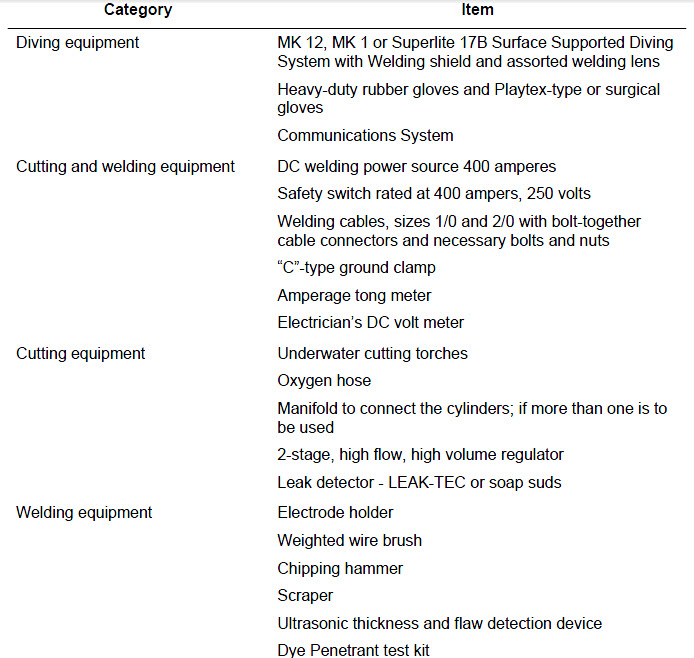

Underwater Arc Cutting and Welding Equipment List:

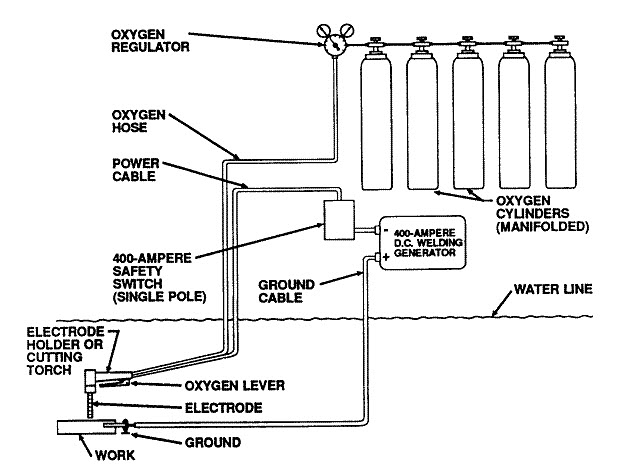

Underwater Arc Cutting Equipment Rig Set Up:

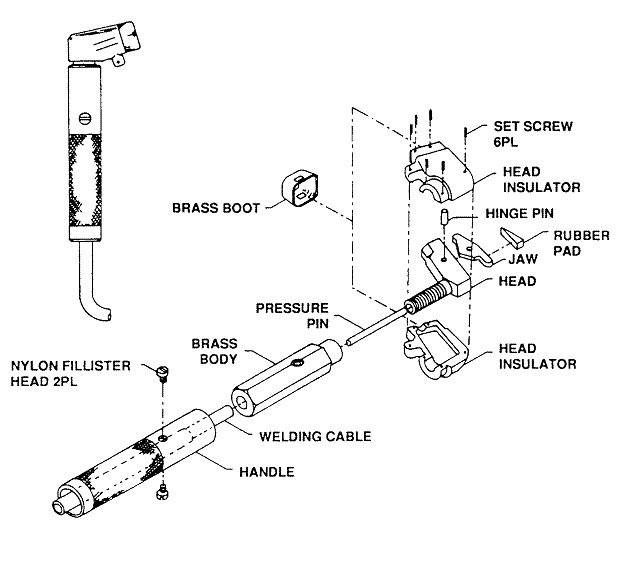

Electrode Holder:

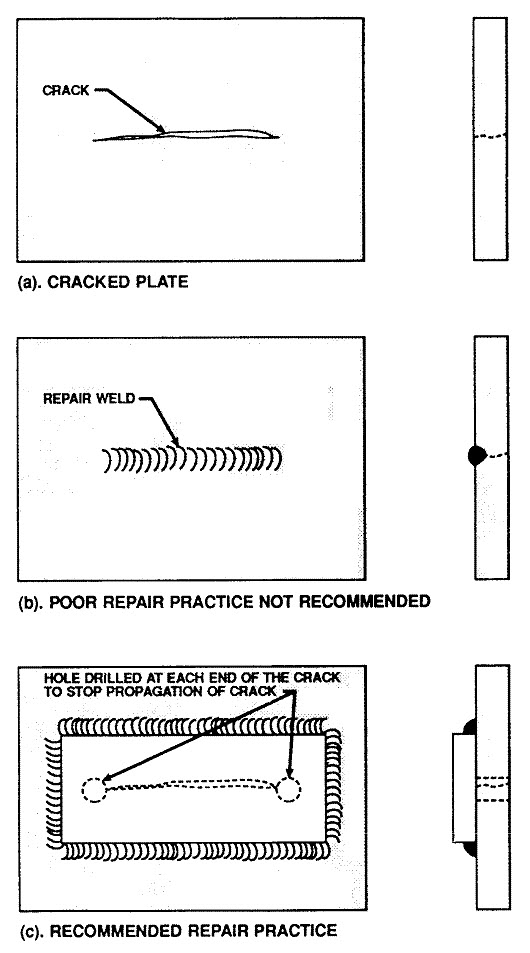

Basic Underwater Rectangular Patch Repair Procedure On Cracks:

An example of a basic underwater welding patch repair job is as follows (see image above).

If there is a crack in an underwater steel structure a common method for repairing it is to use a patch that is rectangular in shape.

- Step 1: Use a three inch radius to round off the patch corners.

- Step 2: Put the rectangular patch with the rounded corners on the crack to be repaired. Use a fillet weld on it. You need to allow for venting so don't lay a bead on the top three inch section of the patch on your first root welding pass.

- Step 3: If you need to avoid welding in the overhead position you can try changing the angle of the patch by turning it about forty five degrees.

Related Articles:

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: