Vertical Stick Welding Tips!

In this tutorial we will go over vertical stick welding techniques.

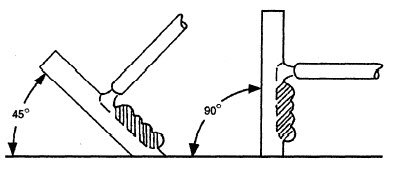

Vertical welding is simply when you weld a joint that is at a vertical angle. This angle is going to be 45 or below.

If you are going to be welding framework for a building or something you will find that this is a very common position to be welding in.

Flat and horizontal stick welding is much easier than vertical stick welding because Sir Isaac Newton's law of gravitation is in full force here.

The molten puddle wants to go down. So you have to use the proper arc welding rod. And the type of welding rod you want to use will be either the fastfreeze or the fillfreeze welding rods.

When you weld in the vertical position you will either go up or down. The technical welding terms for this are: Vertical Up, and Vertical Down.

You can use the Vertical Down welding technique on metal that is lighter gauge. The reason for this is because lighter gauge material does not need deep penetration and therefore you are less likely to burn through it.

If you can weld your material using the Vertical Down technique you will find that it's much faster than Vertical Up.

Vertical Up and Vertical Down Current Settings and Welding Techniques:

Your stick welding current settings should be lower than what you would use if you were welding the the flat position and with the same type of welding rod.

Also, when you are vertical up welding you will adjust your settings a little higher than if you were down welding on the same vertical material.

If you really want a nice weld it's crucial to have a good angle with your rod and your base material.

Here Welding Techniques For Vertical Stick Welding:

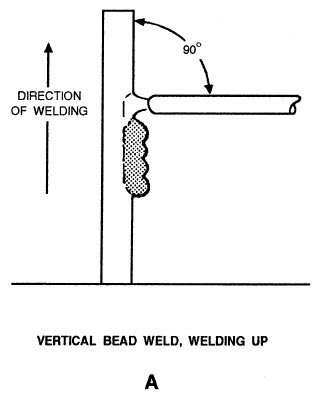

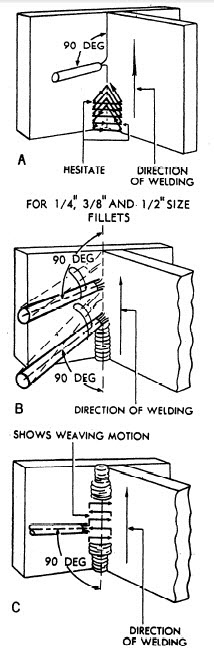

Welding Up: Hold welding rod ninety degrees (See illustration A below).

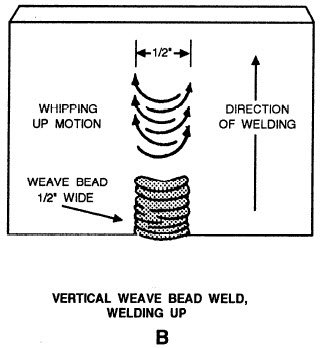

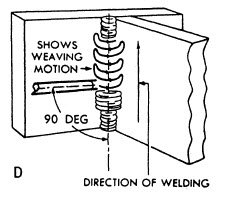

Weave Welding: Use a back and forth weaving motion as shown below:

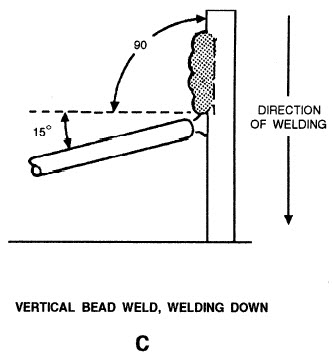

Vertical Down: Tilt your rod fifteen degrees but maintain your arc up in

the direction of the melted metal:

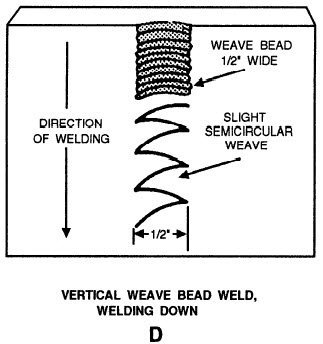

If you need to create a weave weld bead when vertical down welding you will need to use a Z type weaving back and forth motion:

Joint Types:

The most common type of joints you will weld in the vertical position with a stick welder is the Tee, Lap, and butt joint.

If you are going to do a vertical fillet weld in a tee joint or a lap joint

your welding rod should be approximately ninety degrees to the material. If it's off by more than fifteen degrees you will not have a very good handle on the melted metal and therefore you will not have a very good weld.

Also, your arc should be just right in order to get a quality penetration.

If you accomplish good control of your melted metal and your arc is short enough to create good penetration you will have the weld fusion you are looking for. And that means you have a really good weld.

Vertical Tee Joint Welding Techniques:

Vertical stick welding a tee joint requires you to weld from the bottom up:

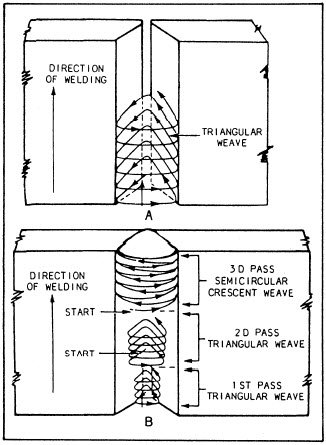

- A good technique is to guide the welding rod in a weaving motion in the shape of a triangle. See illustration A for that. However, if you pause for a brief moment after every few triangles you will get better penetration and fusion.

- If you find that the welding rod filler material gets overheated take the rod from the weld crater but do not break the arc. See illustration B for this technique. The reason this technique works is because it allos for the liquified filler metal to harden but not drip down. Then, bring the welding rod back to the weld crater so that you can keep the size of your weld where you want it.

- When more than one pass is necessary to make a tee

weld, you may use either of the weaving motions shown

in figure 7-37, views C and D. A slight pause at the end

of the weave will ensure fusion without undercutting the

edges of the plates.

Vertical Lap Joint Welding Techniques:

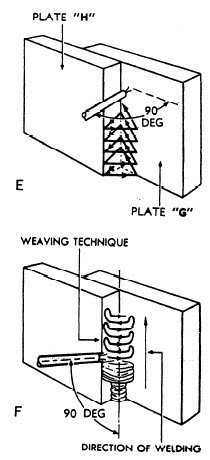

The triangle weaving technique comes into play once again for vertical stick welding a lap joint. See illustration E below to see how. It's the same techniques as shown in the Tee joint example above. But the only difference is that you will tilt your rod in the direction of the metal which is G (in illustration E):

- Again, briefly delay your welding and be careful that you don't get any of the filler material to go over the weave edges you made.

- If you are vertical stick welding on thicker material then you will probably need to do two or more passes (more than one weld bead). In this case you will need to clean your first weld bead and lay your stick welding beads just as they are illustrated in F below.

- Use the same techniques I described in the section on Tee joints to prevent any potential problems.

Vertical Butt Joint Welding Techniques:

There is no difference in how you prepare a butt joint in the vertical position or flat position, so prepare the edges and material the same way.

As with all welding procedures your goal is to achieve a quality weld. And to do that you need to have excellent penetration and fusion of the filler material and the walls of your metal. You also want to avoid any potential undercutting the sides of your metal.

In addition to the techniques described above you will help your cause by controlling your arc and keeping it short.

You can weld a butt joint up to .25" in a single pass (one weld bead) if you use the triangle weaving stick welding technique as shown in illustration A below.

But if you are vertical stick welding on .5" material or thicker you'll need to do multiple passed (more than one or two beads). See illustration B below.

Your last pass should be in more of a half circle motion and like a weave, but at the weld beads edge you 'whip it', 'whip it good!' Sorry I couldn't resist a Devo reference...anyway, you'll whip up your rod and stop welding for a brief moment at the edge of the weld so that you get a quality but wider weld over your previous passes and you'll avoid any potential undercutting or your metal this way.

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: