3 MIG Welding Metal Transfer Methods!

There are a total of three different mig welding transfer types:

- Short Circuit Metal Transfer.

- Spray Transfer

- Globular Transfer.

What decides how the transfer of metal occurs? It depends on the voltage, current, electrode, and gas settings, sizes, or amounts.

Spray Transfer:

Also known as spray arc transfer, this type of metal transfer occurs when you elect for a high current. The result is that your molten metal comes out very fast, like a spray.

In short circuit metal transfer the arc is on and off. But with spray arc transfer the arc is on continuously. You need a higher voltage setting, usually greater than 24 volts, and you also need faster wire feed speed.

Spray transfer creates hundreds of drops of molten metal which are expelled from the electrode every second. Also, since the drops are much smaller, so small in fact that they are smaller than the length of the arc, and as a result short circuiting does not happen. Additionally, you do not get any spatter (or maybe a tiny bit).

This is type of mig welding can be used on thick metal due to the fact that it will penetrate the metal deeply.

Also,

your gas mix is an important factor for spray transfer to work

effectively. Usually you will have pure argon or a mixture of both argon

and oxygen. The reason argon is used is because it helps the electrode

create smaller amounts of molten metal which gives you a little more

control of the process. Argon creates a narrowing effect on the molten

electrode metal being deposited.

Some welders use spray transfer on aluminum. However it's not effective on thin metal because it will burn through.

Globular Transfer:

Globular transfer got its name from the big globs of metal that form and are expelled from the end of the electrode wire into the weld puddle.

The globs are much larger than the droplets produced in short circuit or spray transfer and produce excessive spatter and uneven weld.

This type of mig welding occurs when you have your currents settings low, which creates small 'globs' of molten metal to be deposited slowly compared to spray transfer or short circuiting.

Conversely, you can create more globs when you turn your current setting up.

When you use this type of mig welding the molten metal at the tip of your electrode grows in size prior to being deposited or 'transferred' on the base metal.

With globular transfer you will not create an effective weld. It is undesirable because the globing effect often creates a bad arc which goes out frequently, you get terrible penetration, and you also get lots of spatter.

There are few times you'll use globular transfer. However, some welders have found it useful for certain thin metal applications. Other than that it's not a good way to weld.

Short Circuit Transfer:

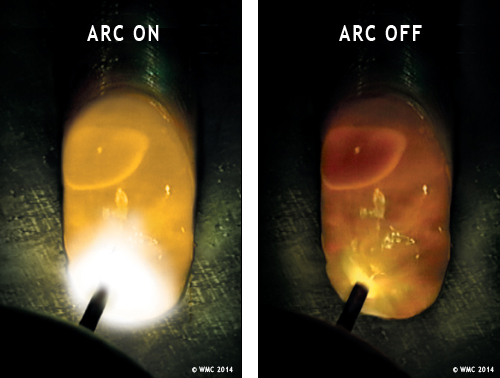

Short circuit transfer got its name because when the electrode wire touches the base metal it short circuits.

When the electrode wire tourches the weld pool it short circuits which turns the arc off, and then the arc is turned back on instantly. This occurs rapidly over and over.

It's commonly referred to as a short arc. A short arc is used to control your puddle more effectively in all positions, and is an effective mig welding technique for the overhead welding position and the vertical position. Welding overhead or vertically makes it more challenging to control the puddle, so short circuiting is used.

In addition, this type of mig welding was created to control spatter on thinner material, burn through, and limit distortion.

You

will find short circuiting to be at amps less than 200, and used on mig

welding electrode wire of .045 or below. The reason thinner diamter

wire is used is because the molten weld puddle is easier to control due

to it's smaller size.

Carbon dioxide (c02)and argon mixes are used (75/25). Argon is for spatter control and c02 allows for more heat and travel speed. Many welders use 100 percent c02. But using only c02 will create an uglier weld bead.

Copyright WcWelding.com All Rights Reserved.

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: