Hot Rod Frame Build!

Building a hot rod frame is not for a novice unless you have a seasoned metalworking buddy who's built a hot rod chassis before. But it's fun! So get to it. You can build your own hot rod or even sell the chassis and then move on to another welding or metalworking project.

With that said, lets begin (by the way the chassis

and jig images are very basic and we are going to update them in a few weeks,

thanks for your patience big guy).

When looking to develop your welding

skills, even when at a very high level, there is nothing better than advanced

welding

projects. The issue many have with advanced welding

projects is that a welder is normally at a very high standard so will only want

ot undertake projects that they feel will benefit them in honing their skill

and also building something of use.

Today we are going to talk about building a Hot Rod frame, something that many welding enthusiasts who also have a love for cars will certainly enjoy. While a hot rod chassis may look basic to the untrained eye, it is actually the back bone or spine to the whole hot rod. A hot rod chassis is the frame that holds the whole hot rod vehicle together. A chassis and a frame are pretty much the same thing so don't get confused as we use one or the other...

Without further adieu its time to get involved and show you one of the greatest advanced welding projects where you can build your very own hot rod frame.

Hot Rod Frame Jig

Before you can even build your hot rod chassis you

will need a jig to maneuver your chassis and support your building process. In

light of this we will talk about building the jig, then talk about building the

hot rod chassis.

To build a hot rod frame jig you need a few lengths

of 5cm box section and four trolley wheels. First you need to measure out three

lengths of 1.5 meters and cut out the lengths, you then need two lengths of 750

mm, you can now weld the two 750mm lengths on the ends of the three longer

lengths. This will means you end up with an image like below:

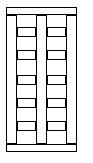

After this measure the space between the three longer lengths horizontally and cut and weld small pieces of box section between so you have the below jig:

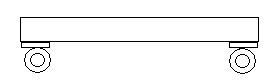

Throughout the process ensure that the hot rod frame jig is as flat as possible. Now you can weld the four trolley wheels onto the jig, one on each corner. The idea of the jig is to give you a flat and portable work space as the hot rod frame will be heavy in weight once complete.

Hot Rod Frame:

To build your hot rod chassis you will need box

section, metal plate and a good welder, oh and you will need to follow the

below instructions

- Think

about the full length you wish to have your chassis, everyone wants a chassis

of varying length so this is important. Once you have decided on your length

divide it into three figures, one being fifteen percent, the other being thirty

five percent and the final one being fifty percent.

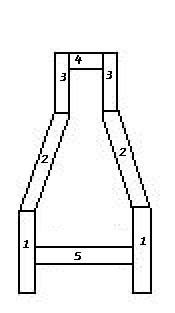

- Take your box section and cut two lengths at your thirty five percent figure (fig. 1 in example below)

- Take your box section and cut two lengths at your fifteen percent figure (fig. 3 in example below)

- Take your box section and cut two lengths at your fifty percent figure (fig. 2 in example below) now cut angles at opposing ends at twenty degrees, each end cut at the same angle.

- Lay your lengths down on your jig and assort them from fig. 1 to 3 in the image and weld them together, you should now have two longer lengths.

- Its time to cut a piece of box section at the required width at the narrow section for your hot rod chassis (fig. 4 in example below). This is to be welded between the ends of the length that represent fig. 3.

- You will now need to measure between the wider end of your hot rod frame and cut a piece of box section to this length (fig. 5) then weld this in-between. Ensure you leave a good 200 mm between the end of your chassis and the welding point.

You will now have a hot rod chassis that fits the

dimensions in width and length you require and that will also be the right

design to house all the vehicle parts you need, similar to the below:

To ensure your hot rod chassis has the strength and stability required you can take your metal plate and cut this into the same width and length of the front and rear box section. Now you can weld these on to the underside of your chassis at these sections, this will add strength to these areas where the most stress is caused.

Many people overlook the need for a jig and think

they can get busy with their hot rod frame without one. The problem is that

after building the hot rod frame they end up in an awkward situation as they

cannot move what they have built. At this point your chassis will be extremely

heavy and this is where you will be thankful for the maneuverable jig so you

can push the chassis to where ever you need.

Related Advanced Metalworking

Projects:

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: