What Is Fusion Welding and Why Is It Used?

Fusion welding is a welding process that fuses metal together using oxy acetylene gas along with filler material (rod). Oxy acetylene welding uses a torch flame to melt the pipe joint metal, and then you add the filler metal as you weld, fusing the joint.

Fusion welding can also be used without filler metal. It's also a good alternative for butt welding of thin material, like plate or sheet metal because you do not use as much heat as with MIG or TIG.

Is it the strongest way to fuse metal together? The answer is no if you are not using filler material. It can break if put under pressure, depending on the joint being welded. Using filler material is the strongest method of welding, whether you are using filler metal with the gas welding process or MIG and TIG welding. But it is a strong welding process and it has it's uses.

Fusion Welded Sheet Metal:

|

Good

|

When is it a good time to use this welding process? You'll get varying opinions on this, but as I just explained it is a good way to weld thin material together if you do not use filler rod. And one reason for that is because when you weld thin material you don't need to grind or flatten the weld very much.

This video is a demonstration of how the fusion welding process is used on a corner joint. Notice that he will end up with a smoother weld and therefore it requires very little grinding. The torch used is a Henrob 2000.

Another advantage is that you are going to have less warping and shrinkage of your material versus the MIG or TIG welding process.

Certainly you can MIG or TIG weld think material, but fusion welding allows you a little more room for error and therefore you'll have less burn through, and the weld can be smoother as well.

It's all a matter of preference and you'll get varying opinions on this especially from the old timers!

Pipe Fusion Welding!

When you gas weld pipe it is proven that fusion welding makes welds that are as strong as the pipe.

To make a good oxy acetylene pipe weld three things need to be in play:

- You must have a good source of controllable heat.

- The oxides must be properly removed prior to welding the pipe.

- The edges of the pipe that you are joining together have to be made with molten metal.

When you weld pipe with this procedure you will melt the metal of the pipe and add filler material of the same metal type as the pipe. The final result should be as strong or stronger than the pipe itself.

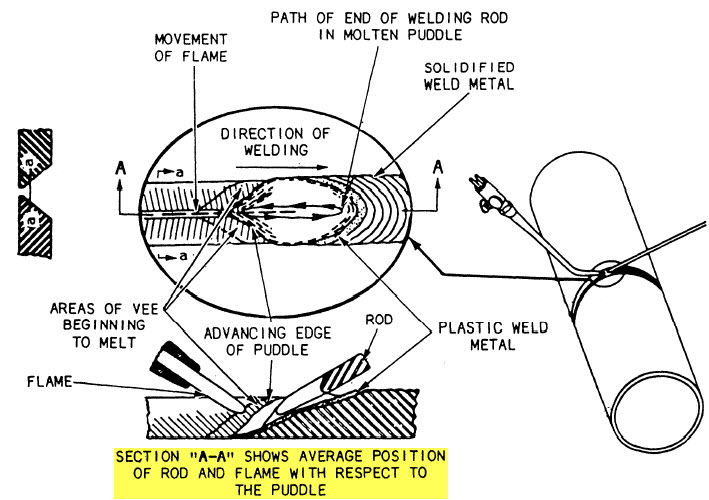

An Illustration Of Pipe Fusion Welding!

The illustration above shows you a pipe in the horizontal position using the fusion welding procedure, but using a backhand welding technique.

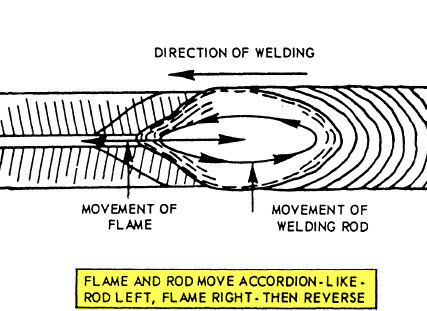

In this illustration above you can see how the welding rod and the torch flame are moving in an accordion motion - back and forth, too and fro.

The advantage of this welding process is the you can make strong welds in any position.

Fusion welding, like most welding is requires a few things to happen to keep the molten metal from dripping or running in various positions. You need to have the flame right, control the puddle, and orchestrate the welding electrode (rod) all at once to keep this from happening.

The electrode you use is very important because the strength and quality of your weld depends upon it.

There is another technique you can test. You may find it a better way to weld pipe than the technique described above. Here's how it works:

- Use a carburizing flame with your acetylene torch: This is also known as excess fuel gas. When you use a carburizing flame the base metal sucks up the carbon that is being emitted from your flame as it get to a white hot point. When this happens the melting point of steel is lowered and then the surface area turns molten faster, and therefore welding speed increases.

- Filler metal: Use a welding rod with deoxidizers in it. The reason for the deoxiders in your welding rod is because it removes contaminants and or impurities as you weld which can cause the metal to oxidize, which is not good. Oxidation destroys welds. If you use a welding rod without deoxidizers you will not get the strength in your weld. Conversely, you will achieve a weld that is stronger or at least as strong as the pipe itself.

- Backhand Welding: When you use the backhand welding technique you get the base metal to melt quicker which increases your travel speed as you weld. It is said that this technique can save you up to thirty percent in overal time welding, welding rods, and the gas you use. So it's worth it if you are going to be doing a lot of fusion welding.

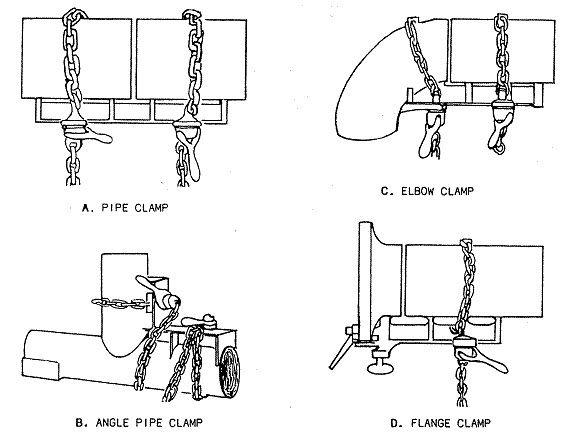

Pipe Clamps:

This diagram illustrates the 4 kinds of clamps used in pipe welding.

A pipe clamp is an exceptional tool for welding because the clamp keeps your joint in alignment as you weld. You cannot afford to have the pipe to be off alignment, even just a little bit, especially if the pipe carries toxic or dangerous materials.

A pipe clamp is easy to operate because they are easy to fit on the pipe and you can open them up fast.

When clamps are not at your disposal consider making your own clamps. Some welders get some angle iron and weld 2 C clamps to it. Make sure the angle iron is quite heavy. A commonly used thickness is 3/8 inch, and 4" x 4" x 12".

For more pipe welding tips read this tutorial which describes more options for welding pipe of small and large diameter.

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: