Arc Welding Rods Explained:

Here's how arc welding rods work in a nutshell:

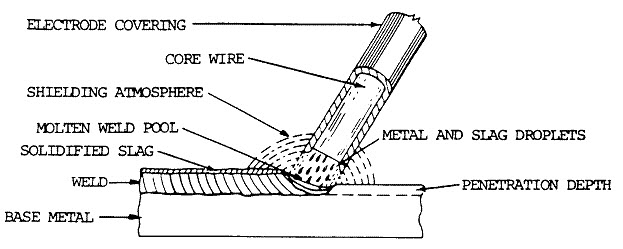

- You strike an arc between a welding electrode (the rod) and your metal piece.

- As you create a weld the welding electrode covering disintegrates.

- This covering has what are called 'arc stabilizers' and they give off a shielding gas that forces air out which will contaminate and ruin your weld.

- And of course it contains the metal filler which creates your weld.

- Stick welding rods also create slag which actually helps to protect your weld.

Side Bar: The technical term for stick welding is Shielded Metal Arc Welding (SMAW).

Shielded Metal Arc Welding Power Source:

When we talk about electrodes and how to weld with them we have to discuss your power source...

Whether your welding machine is electric or portable, the power source will provide either alternating current or direct current to the electrode.

Alternating current flows in both directions, creating an amperage lag. Certain welding rods have been designed with stabilizers in the flux to help maintain the arc through these lags.

Direct current welding machines provide a steady current in one direction. The direction of flow, called polarity, is determined by how the leads are connected to the welding machine.

DC+ with electrode positive is the polarity typically used for shielded metal arc welding.

The Welding Circuit:

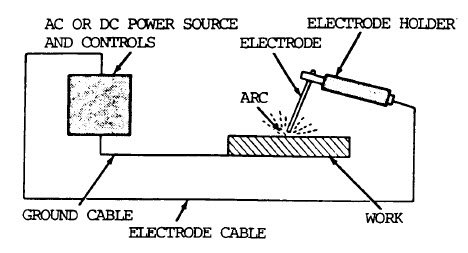

The heat from the arc melts the parent metal as well as the welding rod metal and therefore two pieces of metal are joined together.

The welding rod and your metal you are welding are known in the welding industry as a 'welding circuit' (see image below).

The welding circuit starts with the welding machine which generates the power. But the entire circuit includes more than just the power source, it includes the:

- Welding machine.

- Welding cables.

- Welding rod holder.

- Ground clamp.

- Metal project to be welded, or 'work'.

- Welding rod.

One cable from your welding machine is clamped to the 'work', and the other cable which also comes from the arc welding machine is for the rod holder.

Which Arc Welding Rods Should I Use?

All the common arc welding electrodes used for welding on carbon steel have characteristics that make them better suited for different situations:

The fast freeze rods have a strong arc force that helps burn off surface impurities. A circular or side-to-side motion can be used to build up weld or, because of the light flux coating, these rods can be stepped to provide maximum penetration.

In the vertical weld position, 6010 and 6011 welding rods can be run either uphill or downhill.

6010 And 6011 Rods Are good Rods For 4 Types Of Welds:

#1. Tacking up weld joints:

#2. Welding Metal That Is Slightly Rusted:

#3. Filling Gaps In Poorly Fit Joints:

#4. As A First Pass For Good Penetration:

The filler rods don't penetrate as deep. They

build up weld.

Stabilizers in the flux make 6013 welding electrodes one of the simplest rods to use.

With a slightly heavier slag covering, try to keep the arc in the

puddle. 6013 rods can also be run either up or down on vertical welds.

For general purpose welding, 6013 welding produces a smoother finished weld bead.

7018

arc welding rods contain iron power in the flux and low hydrogen

characteristics. Except for directly under the arc, heavy slag covers

the entire weld puddle as you can see here:

Either running straight or with a side-to-side

motion, the arc needs to be maintained on the leading edge of the

puddle.

In the vertical position, 7018 is run uphill.

7018 required better rod control but does provide the strongest weld for

heavy stress situations and also the smoothest weld for ornamental type

products.

Welding rods are available in different amounts, and it's a good idea to have both fast freeze and filler rods on-hand.

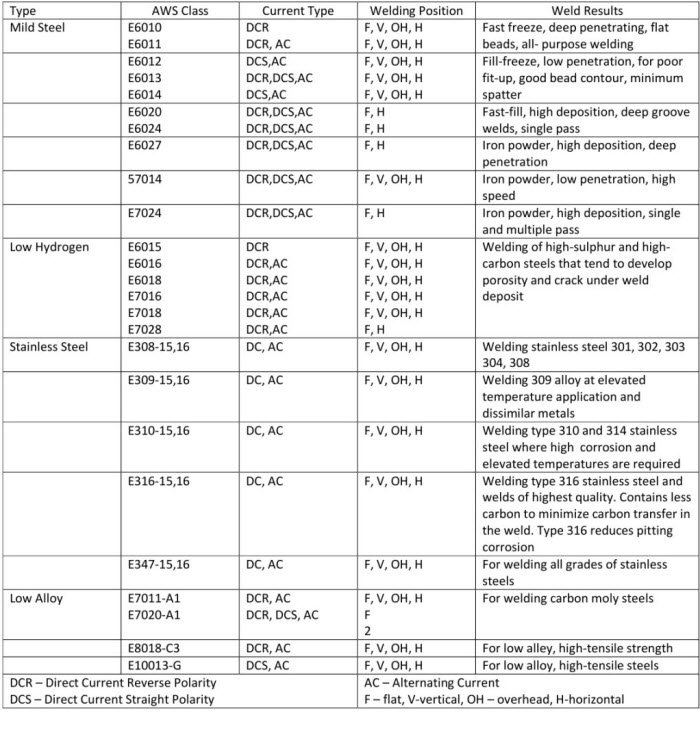

My Old Arc Welding Chart

(Click Image For Larger View):

Below is an arc welding chart from my old files. Feel free to view it or print it out. If you want to print it out you can either click the image for a larger view and click print or here is my stick welding rod chart in PDF format.

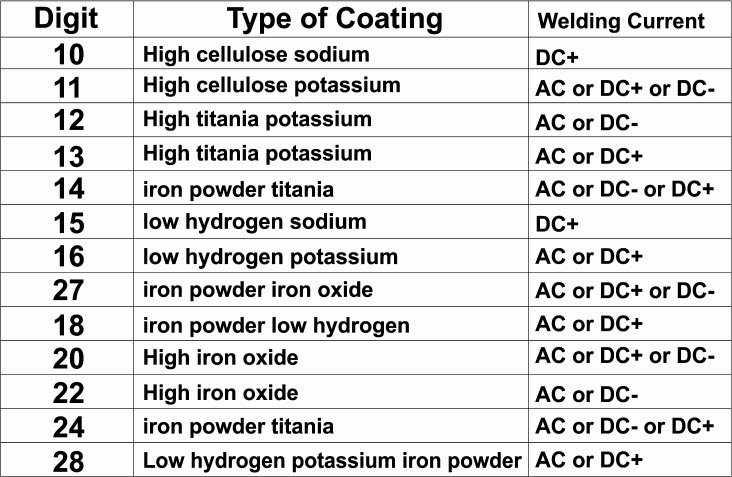

Understanding The Last Two Digits:

Look at the last two digits of your electrode. The first number in the the two digit number tells you the position you can use the electrode in*.

1 = any position.

2 = horizontal position and flat position.

3 = flat position only.

4 = overhead position, horizontal position, and vertical down and flat positions.

*After you figure that out, you have to use the last two digits together to figure out what the coating and polarity the electrode can be used with.

The chart below makes it easier to tell what the last two digits of your arc welding rod classification means. It shows you:

- Type of coating.

- Current.

- Position.

Here's What All The Numbers Mean:

Let's use the good old E6011 arc welding electrode as an example:

E = Electrode (Sometimes there's ER which means either Electrode or Rod).

60 = 60,000 pounds per square inch tensile strength. So this number is the 'tensile strength' of the material (the weld you will create with the rod).

1 = All Positions (you can weld in all positions with the rod).

1 = This is a little confusing but as explained above you often have to combine this number the previous number (in this case it will be 11) to find out what the welding rods coating and polarity is. Look at the chart above to find out what 11 indicates.

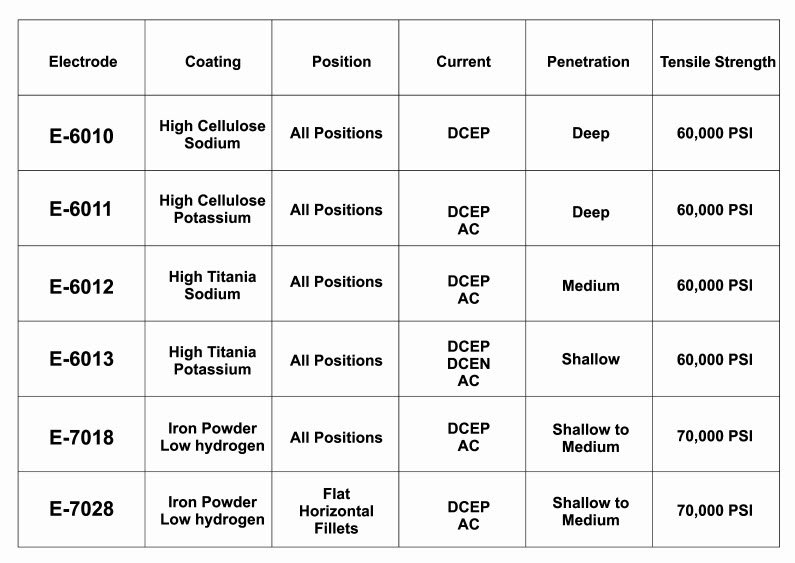

6 Common Arc Welding Electrodes Used for Welding Mild Steel:

The next chart below is similar to the one above but it gives you more detail on the six top arc welding rods.

It shows you: coating, welding positions, current, and tensile strength for each arc welding rod.

For example, if we look at the E-6010 rod, the chart below shows you that the

coating is high cellulose sodium, you can weld in all positions, it has deep penetration, and the tensile strength is 60,000 psi.

- DCEP = Direct Current Electrode Positive, or direct current and reverse polarity.

- DCEN = Direct Current Electrode Negative, or direct current and straight polarity.

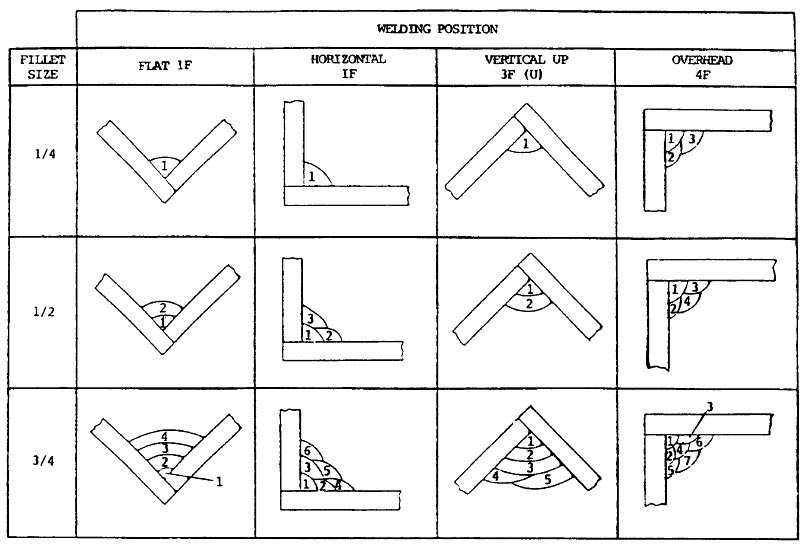

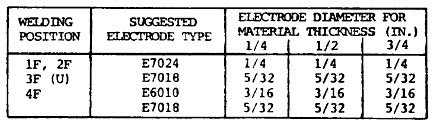

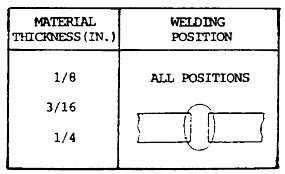

Fillet Weld Size and Welding Position Chart:

Fillet Welding Position and Arc Welding Rod Type:

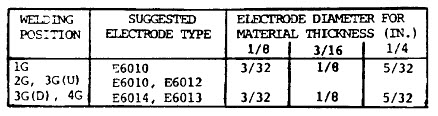

Groove Welding Position and Arc Welding Rod Type:

Storing Arc Welding Rods:

Did you know that moisture kills electrodes? That's right, moisture is the ultimate enemy of your welding rods so you have to keep them in a dry place.

OK, maybe I am exaggerating a tiny bit but moisture is very bad for arc welding rods because if they do get moisture in them they will tend to spatter, sometimes a lot. But worst of all this can cause cracking in your welds, which is unacceptable.

The good news is that if your welding rods have been in a damp environment there is a way to get them back to near normal.

The rule of thumb, by the way, is if your electrodes have been in a moist or damp environment for more than two hours you can dry them in an oven...

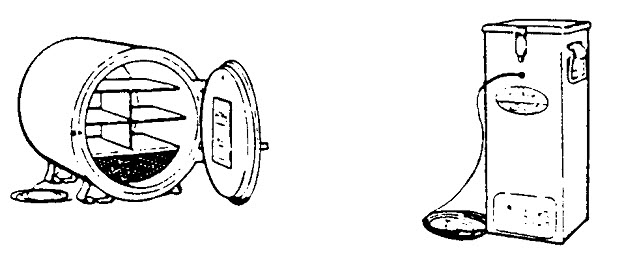

Electrode Ovens:

It is said that you can dry arc welding rods at 500 degrees Fahrenheit or 200

degrees Celsius for two hours. But check with your electrode

manufacturer to be sure it's suitable for your particular rod.

As described in our Arc Welding Tutorial, a poor mans dry storage area is an old refrigerator. Otherwise any storage that is moisture proof should be just fine.

Side Note: Do not bend your arc welding electrodes because the coaiting will break off exposing the wire, and if the wire is exposed you should not use it.

The image of the ovens are specifically for drying electrodes like this portable electrode drying oven.

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: